JEM PPF-Black Gloss JB8 Protective Colored Film cena za 16mx1,5m

| Category: | JEM PPF Colored Films |

|---|---|

| EAN: | 8594228080026 |

JEM PPF-Black Gloss JB8 Protective Colored Film

JEM PPF protective film is the most effective paint protection. Innovative technology has helped us create a product with high self-healing properties, hydrophobicity, and dirt resistance. Once applied, the film forms a protective barrier on the paint that prevents mechanical damage caused by scratches, scuffs, and stone chips from debris kicked up by tires.

The PPF film is made of high-quality thermoplastic polyurethane (TPU) with a scratchcontrol coating, giving it excellent self-healing properties. Scratches heal when exposed to heat (sunlight, warm water, engine heat).

Thanks to its hydrophobic function, the film remains free of stains and dirt buildup over time.

The protective film, with its anti-contamination surface treatment, ensures paint durability against all chemical factors threatening the paint's safety. It protects against harmful substances on roads, including salt, harsh chemicals in car washes, acid rain, bird droppings, insect residues, and tree sap. After applying the protective PPF film, you can be confident in adequate protection.

Basic Technical Specifications:

- Width: 1.52 m

- Length: 15 m

- Thickness: 185 µm

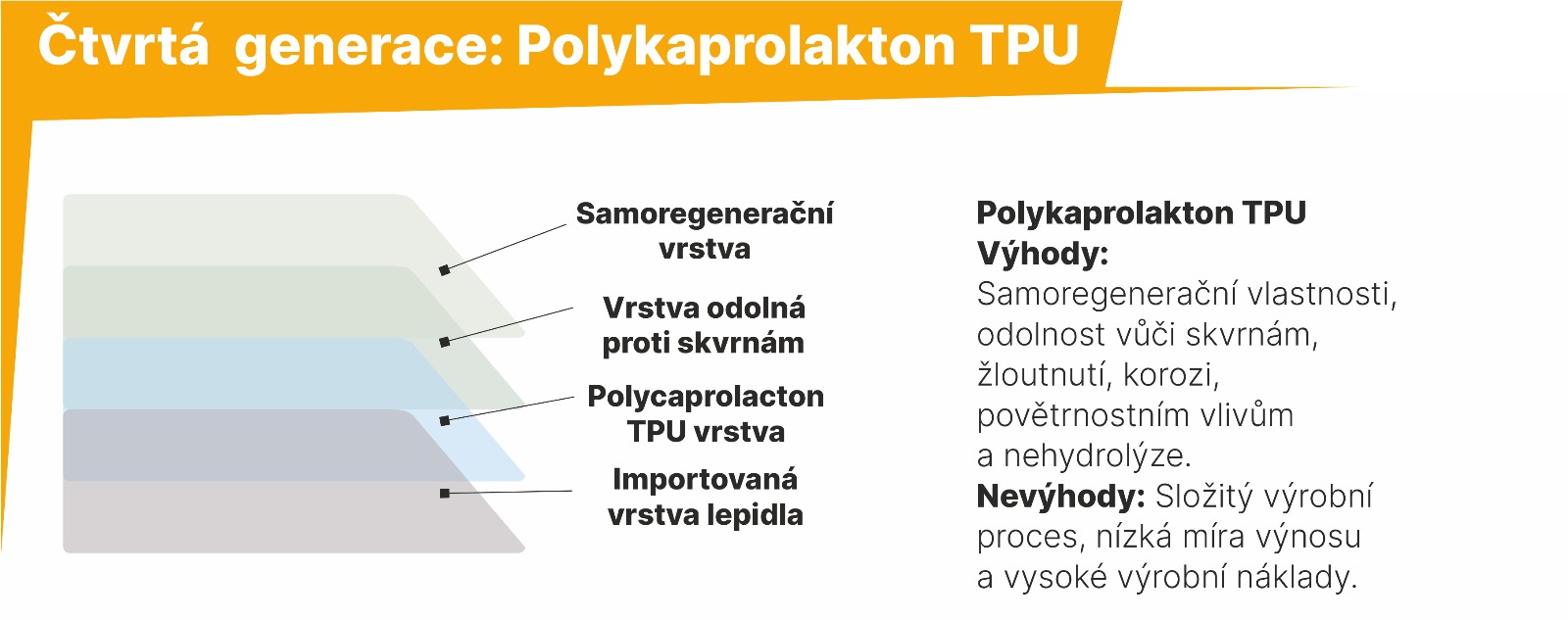

- Type: Polycaprolactone TPU

- Color: Black Gloss

- Surface Finish: Glossy, hydrophobic

- Quantity: 1 roll

- Warranty: 10 years

Must read before application

- If possible, remove from the vehicle parts that could release contaminants during application (badges, trims, logos, lights, handles, etc.).

- Wash the vehicle thoroughly. Remove any contamination on the paint (asphalt, flying rust, adhesive residues from the protective film used during transport, etc.).

- After setting the vehicle for application, it is recommended to use wheel covers and connect the vehicle to a maintenance power source.

- Try to minimize dust around the vehicle and avoid applying the film in clothing that may release lint.

- Dry PPF film, after peeling off the backing layer, is charged with static electricity, so it's important to work in a way that prevents dust particles from attaching to the adhesive side.

- Use the proper solution and application technique to avoid damaging the adhesive and creating unwanted streaks, bubbles, or tears in the adhesive.

- Degrease the edges of the part being applied with clean IPA, and before applying, decontaminate each part with soft clay.

- Lightly spray a shampoo and distilled water solution (distilled water won't leave spots after drying) on the part being applied and both sides of the PPF (use 2-2.5 ml of shampoo per 500 ml of water, more shampoo is suitable for higher workshop temperatures or when applying complex parts).

- The shampoo solution will protect the adhesive during handling and positioning the PPF on the part but will not activate the adhesive on the paint. Therefore, it is necessary to rinse it with clean water, preferably distilled, poured from a pressure sprayer in large amounts.

- To set and stretch the material, grab the edges of the film on adjacent parts and rinse the shampoo solution outside the part to which PPF is applied (catch the hood on the fenders and at the bottom on the lights and bumper).

- Carefully squeegee any excess shampoo solution to remove any remaining solution or bubbles and rinse the edges with clean water.

- If you need to attach the material immediately, use a distilled water and IPA solution in a 1:3 ratio.

- Dry the applied film with a towel and check for any debris or water residues under the film.

- Trim excess material 3-4 mm for folding over the edge, depending on the part type.

- Immediately fold using nonwoven fabric and a heat gun. Gradually push out all the water from the edges while heating the side with the adhesive using a heat gun set to 65°C.

- You can hand over the vehicle after 24-48 hours, depending on the season.

Choosing the Correct Film and Precut Implementation

- If you don't have the vehicle in your workshop, request photos of the vehicle from all sides and send the photos to us with vehicle details.

- We will quickly check if the vehicle model in question is in our database.

- In some cases, it is possible to supplement the data for a vehicle that is not in the database.

- When ordering materials, remember to consider the vehicle color. A different film is applied to dark colors than to white vehicles. The material for white vehicles is specially designed with increased UV resistance.

- We offer glossy, matte protective films, in 180 cm width, light tinting for lights, heat-resistant films for sunroof windows, and of course, colored films with the option of applying without water.

- After consultation, we will create a custom precut tailored to your specific order and ship it on the same day as the order.

- Always check the material upon arrival with the delivery service.

- Before applying, make sure to read the information on the previous pages.

JEM PPF s.r.o. is the exclusive distributor of PPF protective films manufactured by JEM. We offer all necessary documentation, technology, and quality guaranteed by long-term experience in the Asian market. Due to direct connection with the manufacturer, we are able to offer the production of all types of PPF films made to order according to the client's specifications. We ensure all documentation, from insurance, loading, transport, clearance, unloading, to delivery at the destination according to client requirements.

JEM is the manufacturer of the most advanced materials of this kind in Asia, established in 2006, with a history of more than 19 years. With nineteen years of continuous innovations, breakthroughs in technical barriers, and service improvements, the company continues to expand in the field of new materials such as wrap films, PPF protective films, automotive window films, and multilayer optical and electronic functional films.

QUALITY GUARANTEE

The warranty covers: yellowing, peeling, cracking, blistering, and delamination. This warranty does not cover product wear, external corrosion, accidents, collisions, or any form of intentional damage caused by external forces.

QUALITY MANAGEMENT SYSTEM CERTIFICATES

ISO9001 / Quality management system

IATF16949 / Automotive Industry Quality Management System

SGS / RoHS & REACH certification

Be the first who will post an article to this item!